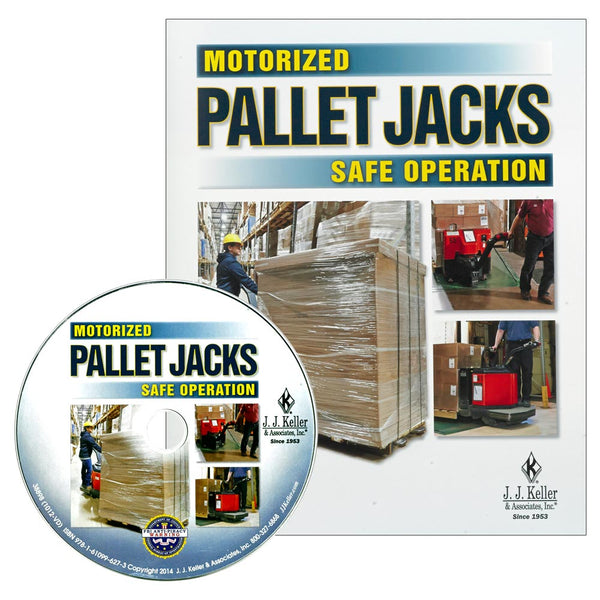

Motorized Pallet Jacks: Safe Operation - DVD Training

Regular price

$515.00

Product Details

- Helps meet the requirements of OSHA’s Powered Industrial Trucks Standard 1910.178(l)

- Takes a unique but practicable approach by focusing on the motorized pallet jack's use from the start of the work day until the end – including the potential dangers and hazards that operators face along the way

- The

Motorized Pallet Jacks: Safe Operation training program covers:

- The two most common types of motorized pallet jacks and their controls

- "Walkies"

- "Walkie-Riders"

- Load and lift capacities

- Common pallet jacks accidents

- Safe operating procedures

- Pre-use inspection tips

- Picking up a load

- Traveling with a load

- Navigating on ramps and inclines

- Maneuvering in tight spaces

- Delivering a load

- Parking safety

- End of the day procedures

- Ready-to-use training program includes several components

- Closed-captioned for the hearing impaired

- The two most common types of motorized pallet jacks and their controls

Program Components

- (1) 20-minute video - Features the latest video techniques and state-of-the-art graphics designed to keep employees engaged allowing for better retention of the information being presented to them.

- (1) Trainer Guide - Product Codes: 38923 (826-H) - A resource for trainers that supplies background information on pallet jacks, training objectives, tried and true training methods, and an overview of the training information covered in the program.

- (1) Trainer Tools CD-ROM (not sold separately) - Features a PowerPoint® presentation, clipart, a training log, and a certificate of completion that can be personalized and printed for each employee who completes the training. Also includes a series of learning activities representing "real world" situations that motorized pallet jacks operators face every day. The learning activities will help bridge the gap between classroom and hands-on training and will help operators become mindful of safe operating procedures and potential dangers.

- (11) Operator Handbooks - Product Codes 38925 (827-H) - This 18-page reference reinforces training. It summarizes the material covered in the video in an easy-to-read bullet format that employees can reference on a daily basis. Also contains a receipt page and a 10-question quiz.

- (1) Awareness Poster - Product Codes: 39454 (726-K -P) - Provides a daily reminder of the importance of operating a motorized pallet jack safely and the potential consequences if operators are not properly trained or if the pallet jack is misused. Full-color.

DVD Main Menu

- Play Program - Plays entire main program (running time: 20 minutes)

-

Chapter Selections – Allows easy access to specific subtopics for more focused training

- Introduction

-

Importance of Training

- Motorized pallet jacks are just as numerous and pose the same kinds of hazards that forklifts do

- Consequences if they’re misused or not operated properly

- Operators need to be trained on the specific type of powered industrial truck they operate. If an operator is trained and certified to operate a forklift it doesn’t mean they’re automatically qualified to operate a motorized pallet jack

- Operations and Controls

- There are many different models of motorized pallet jacks offered by many different manufacturers

- Most common models used in workplaces are “walkie” or “walkie-rider” models

- Lift height and weight capacity vary by manufacturer and model but most can lift a load as high as 6 inches off the ground and can carry as much as 8,000 lbs

- Steering handle regulates the lift, lower, speed, direction and braking

- Common differences among manufacturers and models include:

- Where the controls are located

- How high the carriage can lift

- Load capacity

- It’s important that each operator be properly trained on the specific model they are about to use

- Accidents

- Most accidents are the result of an operator not following safe operating procedures or being unfamiliar with the controls of a specific model of pallet jack. Reported accidents include:

- Pedestrians getting caught between the pallet jack and a fixed object

- Pedestrians having their feet or toes run over

- Pedestrians hit by a falling load (due to an unsecured load and/or too fast turn)

- Operators engaging in horseplay such as riding on a walkie pallet jack

- Operators are crushed or even killed by a pallet jack that rolls off the edge of a ramp or loading dock

- Safe Operating Procedures

- Pre-Use Inspection: The importance of inspecting the pallet jack prior to each use to ensure that any defects are reported and fixed before it is used

- Getting a Load: Proper techniques on approaching and securing a load

- Traveling with a Load: The “do’s” and “don’ts” when traveling with a load including safe travel heights, proper sight lines, correct hand positions on the controls, negotiating intersections, safe turning, and more

- Navigating on ramps and inclines

- Maneuvering in tight spaces

- Delivering a Load: Safe operating techniques such as coming to a complete stop before lowering the load and making sure the forks are completely lowered before pulling out

- Parking: Rules and what steps to follow when parking a pallet jack

- End of Shift: Proper procedures for shutting down and storing a pallet jack for the next day’s use

- Conclusion

- Bonus Materials - Total running time: approximately 32 minutes

- Review: Safe Operating Procedures (Running time: 7 minutes)

- Quiz (Running time: 10 minutes)

- Note to Trainers (Running time: 5 minutes)

- Previews:

- The Forklift Workshop (15900) (Running time: 5 minutes)

- Ultimate HPC: Forklifts (28124) (Running time: 5 minutes)